Strainers and Sight Glasses

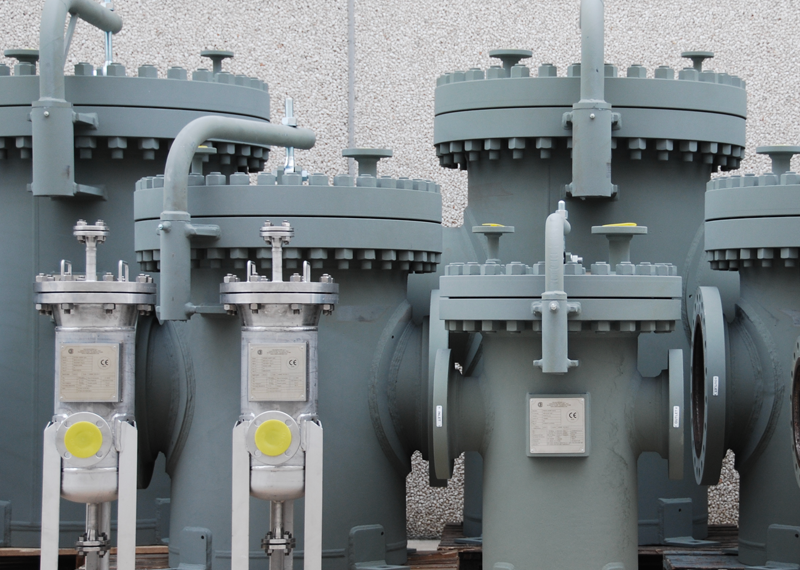

Y Type Strainer

CDB Y type strainers, most probably the largest range on the market, are designed and manufactured to comply with any required design code and international Standard. All supplied strainers are equipped with screens specifically designed and manufactured based on the project requirements. Compared to other manufacturers, CDB strainers are bigger in dimension and weight in order to allow a generous screen surface thus a large open area ratio to ensure an efficient filtration action with a low pressure drop.

Tee Type Strainer

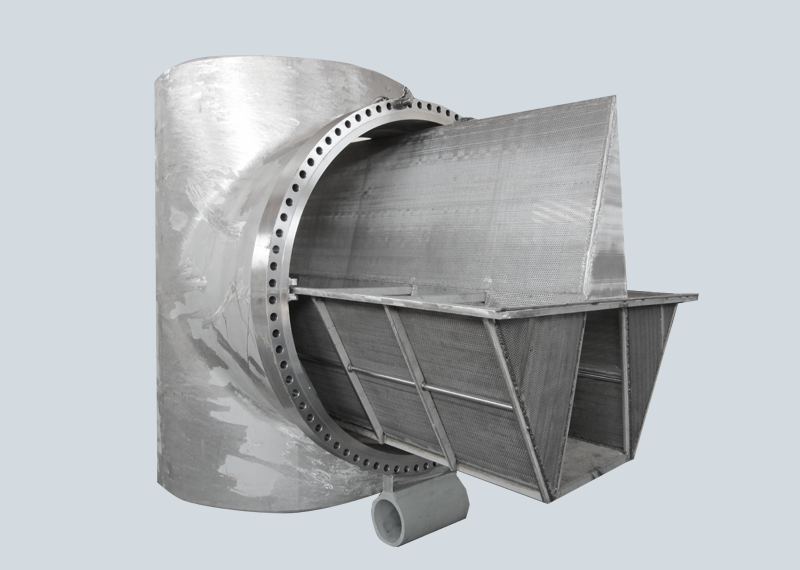

Simplex and Duplex Basket

CDB manufactures both cast steel and welded fabricated basket strainer. CDB strainers meet customers’ expectations and the highest standards. Of all strainers, basket are the type which offer by far the highest filtration surface.

Simplex strainers need service interruption (during shutdowns) or a bypass line in order to clean or change baskets. Duplex strainer can operate continuously and need no shut down for cleaning operations. This type of strainer has two separate baskets that operate independently. When one basket is clogged, the flow will have to be diverted to the other one, allowing cleaning to the clogged one.