Plug Valves are possibly the oldest type of valves used for pipeline applications and their first use dates back to Roman times. Some of the main industries for plug valves are Oil & Gas, Chemical & Petrochemical, Water & Waste Water, Pull & Paper. Plug valves cover a wide range of applications, such as Gas and Oil pipelines, Compressor Stations, Drain Vent, Blow Down, Manifold Isolation and Severe Service.

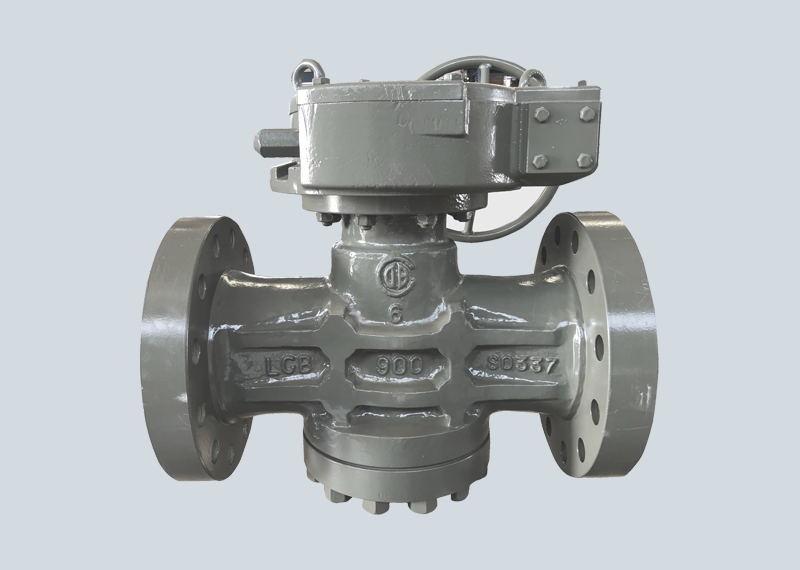

Most of the times, Plug Valves are quarter turn valves for on/off or shut off services but in special cases they are also used for modulating and throttling services. They can be manually operated or actuated, usually through electric, pneumatic or gas over oil actuators. Their simple design, together with the use of limited components, guarantees a compact design with Zero Leakage performances also making the Plug Valve a very reliable product with a long operating lifespan and an easy maintenance.

The main categories of plug valves are:

Lubricated Plug Valves, Non-Lubricated Plug Valves, Double Block & Bleed Plug Valves, Expanding Plug Valves